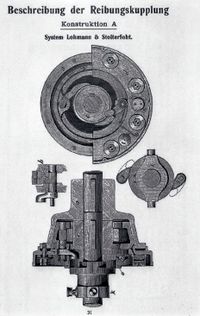

Lohmann Stolterfoht Pneumaflex and Spiroflex Couplings

Max Lohmann and Max Stolterfoht started in 1884 with the brand Lohmann + Stolterfoht. The friction couplings they both invented at the same time were able to shift during operation. They named their coupling the "A" Coupling. After a few years they received a large customer that needed friction clutches: the submarine business. They needed a coupling to connect the diesel with the propeller shaft. Because of these close relations with ship builders, they started to offer complete reverse reduction gearboxes in 1926.

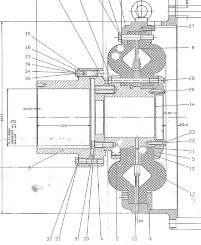

Lohmann Stolterfoht Pneumaflex Range

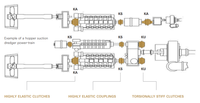

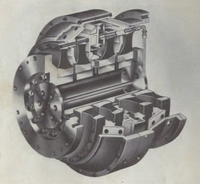

These highly elastic torsionally and vibration damping coupling is pneumatiaccaly operated. It is a double cone friction clutch. This dry operated clutch

Main Advantages:

- Combination of a dry friction clutch and highly elestic coupling without short lived idle bearing system.

- Complete separation of primary and secondary sides.

- Backlash-free, no wear of components subject to backlash

- Smooth and easily controllable engaging operation

- Clutches can be vertically removed.

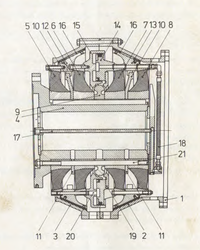

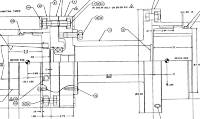

Lohmann Stolterfoht Spiroflex Range

These highly elastic torsionally coupling can compensate off center misalignment and deviations from angular and axial positions. They can prevent damage due to for instance torsional vibrations.

Main Advantages:

- High torsional flexibility

- Different rubber hardness grades available

- Elements can be removed radially

- Backlash free torque transmission

Other Coupling types:

Because of the services we provide for other rotating equipment, we also offer the connecting element.

It does not matter if it's a replacement, an upgrade or a complete new design, we can assist with our preferred partners. Depending on the type and request we will proceed with either our partners, or the extensive network from our supply chain.

Coupling types we can supply:

- Standard flange couplings

- Flexible couplings

- Elastic jaw & pin couplings

- Tooth couplings

- Disc couplings

- Hydraulic clutches

- Safety couplings

- Pneumatic couplings

- Fluid couplings

- Turbine couplings

Vulkan:

Most common coupling used in marine applications is a coupling like the VULKAN coupling

High speed couplings:

For turbines and compressors a lot of gear couplings are used: